Introduction

-

Triaxial shear testing is a widely employed method for assessing the mechanical properties of deformable solids, particularly soils (such as sands and clays), rocks, and various granular materials or powders. Figure 1

In a triaxial shear test, stress is applied to a sample, creating different stresses along orthogonal axes. This is typically achieved by placing the sample between two parallel platens, applying stress in one direction (usually perpendicular), and introducing fluid pressure to impose stress in the perpendicular direction.

Varied compressive stresses induce shear stresses in the sample, with the load incrementally increased until the sample fails. Throughout the test, the surrounding fluid is pressurized, intensifying stress on the pressure plate until material failure occurs, forming a sliding area within, known as a shear zone. The geometry of shear often causes the sample to shorten while bulging along the sides. Subsequently, the pressure on the platen is reduced, and water pressure restores the sample’s height. This cycle is repeated while collecting stress and strain data. The Bishop pore pressure device can measure pore pressure in fluids (e.g., water, oil, or gases) during testing.

Granular materials typically undergo a volume change during shearing. If initially dense, they tend to expand, known as Reynolds expansion. If initially loose, shrinkage occurs concurrently with or prior to shearing.

In “consolidated drained” tests, the sample is slowly consolidated and sheared during compression, allowing pore pressure generated by shear to dissipate. The axial deformation rate remains constant, ensuring controlled strain. This test permits the specimen and pore pressures to fully consolidate in response to surrounding stresses.

Triaxial test data yield essential material parameters, including shear resistance angle, apparent cohesion, and expansion angle. These parameters are incorporated into computer models to predict material performance in larger-scale engineering applications.

-

Why do we consider microstructure expression of granular materials?

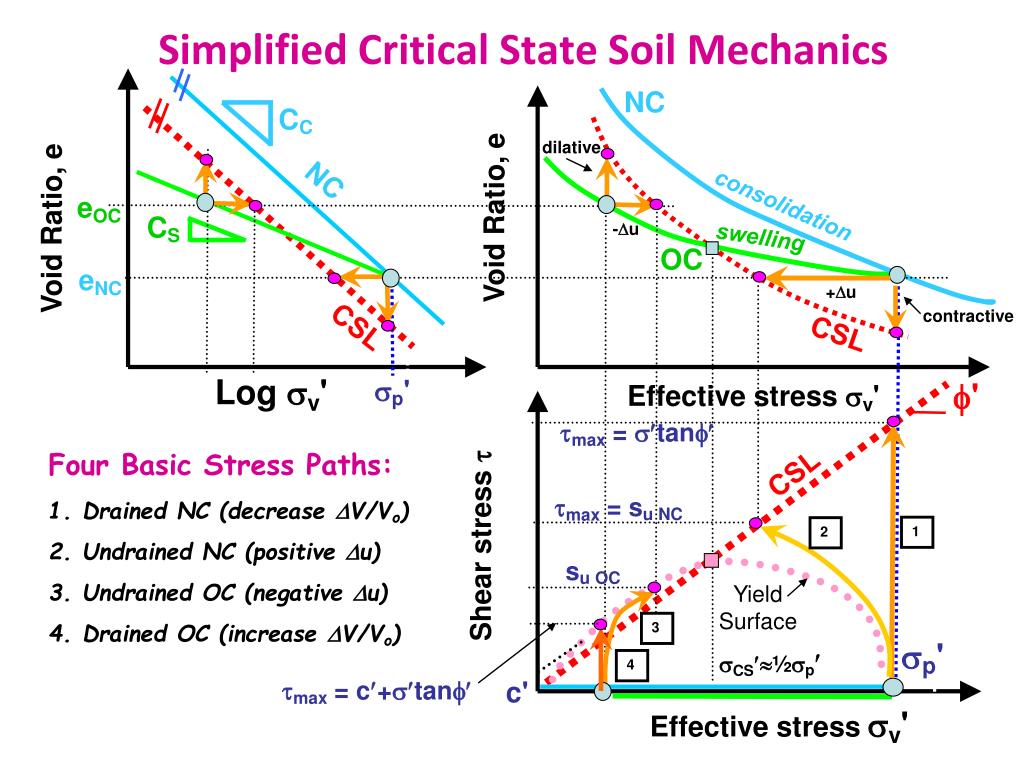

Geotechnical researchers utilize a variety of experimental and modeling techniques to understand the mechanical behavior of granular soils (Terzaghi et al., 1996). One of the most important theoretical frameworks in this regard is the critical state soil mechanics theory (CSSM) proposed by the Cambridge group (Roscoe et al., 1958; Schofield & Wroth, 1968). In this framework, the state of the soil is characterized by the void ratio e and the mean effective stress p’, and is attracted by the critical state line (CSL) in e-p space upon monotonic shear. The critical state line (CSL), also known as the critical [void ratio] line, represents the void ratio-effective stress state reached when all net void ratio and effective stress changes are completed after the soil has been subjected to a large strain.

This framework provides many opportunities to construct constitutive models to simulate soil stress-strain behavior. Most geotechnical studies use first-order geometric descriptors (i.e., void fraction) to describe critical state phenomena.

Recently, Zhang et al. (2020) proposed a new constitutive framework for granular materials called critical fabric theory (CFT). CFT aims to define critical states relying solely on the geometric characteristics of the soil’s inertial structure. Specifically, a second-order fabric tensor can be constructed based on the directional distribution density of contact normals. Critical states in CFT can be visualized as critical structure surfaces (CFS) in the main structure space. It was proposed that CFS attracts the fabric state of granular material when sheared, which is manifested by the fabric path toward the CFS. The classical CSL and CSSM can be recovered after providing some secondary relations linking the contact fabric to the stress tensor and the void fraction of the particle components. Figure 2

CFT provides an alternative perspective on critical state phenomena with several unique advantages:

(1) It unifies various critical state conditions newly discovered in recent experimental studies;

(2) By defining a single attractor, rather than continuously adding different critical state conditions in different spaces, it provides a simpler and more structured framework for modeling granular soils;

(3) The fabric is no longer an add-on component to the traditional elastic-plastic model, but the only carrier connecting strains and stresses, which is physically reasonable considering the micromechanical origin of stresses and strains.

Therefore, the second-order fabric tensor constructed by CFT can be used to visualize the microstructure of granular material, and each contact normal can be described by the position vector of Cartesian Coordinate space. These position vectors can be used to plot direction distribution diagram, which utilizes the directional information of total contact normal (nx, ny, nz) from DEM simulations to illustrate particle interactions.

-

What are the applicatioins of CFT?

The cyclic triaxial test can determine the cyclic strength (also known as liquefaction potential) of the soil by controlling the cyclic load (ASTM D5311/D5311M-13, 2022).

Simple elastoplastic models built upon CFT can model the basic behaviors of granular soils under a wide variety stress paths such as drained and undrained monotonic loading and undrained cyclic loading. The theory has been systematically validated against undrained triaxial compression data on sand with various initial densities. However, the model prediction has not been checked with sand behavior under drained cyclic loading, i.e., the ratcheting behavior. Dynamic triaxial testing is one of the main methods to evaluate the strength and deformation characteristics of soils under cyclic loading conditions.

These cyclic loads simulate the reality of dynamic loads that can come from earthquakes, passing vehicles and trains, waves, wind, vibrating machines, etc. Understanding soil’s liquefaction potential can ensure that the cyclic strength of the soil can cope with the subsequent effects of natural and man-made cyclic loadings like earthquake and traffic loadings.

-

Motivation about DL Applications on CFT

Void ratio is one of the most fundamental states descriptors of granular soils and is widely used in geotechnical engineering practices. On the other hand, the important role of fabric in soil mechanics has been intensively investigated in recent years. A fundamental question, however, remains unanswered: are there one-to-one relations between these two internal variables? The answer to this question has profound mechanical implications. If “yes”, fabric-based constitutive models no longer need to include void ratio in their formulation to recover the conventional critical state line.

With the advancement of Deep Learning, an increasing number of scientists are harnessing the capabilities of Neural Networks to analyze data features and manage vast quantities of information. The application of neural networks in predicting soil stress-strain responses has gained significant popularity as a data-driven approach in recent years. Traditional constitutive models were tailored for specific types of sands or conditions, relying on heuristic evolution laws that are not generalizable to all types of loading conditions. In contrast, Deep Learning, renowned for its data-driven approach, excels in handling nonlinear relationships. The DL model not only circumvents the high computational costs but also alleviates the need for laborious mathematical analysis.

However, it is important to note that most of the deep learning-based modeling in this field has been centered around sequential numeric data for predicting mechanical behaviors and fabric anisotropy evolution. The application of image data to represent fabric information has not received significant attention in geomechanics. Insights gathered from soil images provide an intuitive means of describing soil properties. In this research, our primary focus is on exploring the potential of spatial data, specifically pertaining to directional contacts within soil assemblies, to infer the density (or void ratio) information in granular materials.